Research On Drilling Technology Of Titanium Alloy Gr5 Parts

Research On Drilling Technology Of Titanium Alloy Gr5 Parts

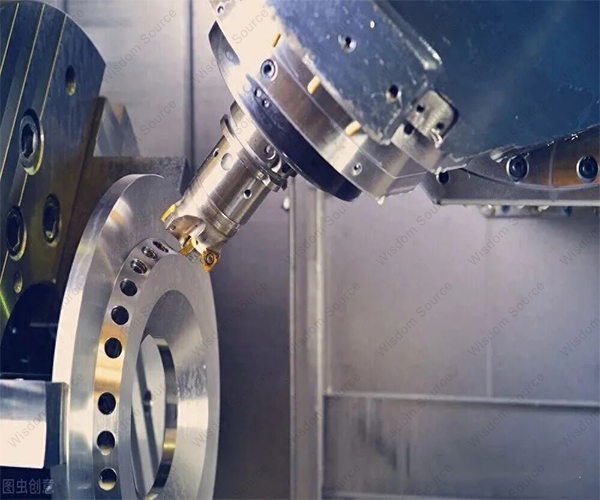

Titanium alloy has the advantages of good thermal stability, small high-temperature mechanical deformation coefficient, corrosion resistance and good bonding performance, and has been widely used in high-end fields such as aerospace. However, titanium alloys have low thermal conductivity and large cutting force per unit area. They face many challenges in the drilling process, such as fast tool wear and prone to problems such as bit sintering, stuck drilling, oblique drilling, and poor size. Drilling is a semi-enclosed cutting. When titanium alloy is drilled, the cutting temperature is high, the rebound is large after processing, the long surface of the chip is thin, easy to bond, and not easy to discharge. It often leads to vicious accidents such as bit biting and torsion grinding, which seriously affect the processing efficiency of parts. Therefore, it is of great practical significance to study the drilling and processing technology of titanium alloy Gr5 parts to improve the processing quality and efficiency.

1. Difficulties Of Titanium Alloy Drilling

(1) The organization of titanium alloys with high cutting temperature is a hexagonal lattice system, with strong binding force between atoms and not easy to get out of the equilibrium position. During drilling, the cutting force does work to generate a lot of heat in the cutting area, and the titanium alloy has poor thermal conductivity, making it difficult for the heat to be transmitted out quickly, resulting in a sharp increase in the cutting temperature.High temperature will intensify the wear of the drill bit, reduce the service life of the tool, and cause thermal deformation of the processed parts, affecting the machining accuracy. Tests by Baoji Titanium Industry Research Institute have shown that under ordinary drilling conditions, the temperature of the titanium alloy cutting zone is 2-3 times higher than that of carbon steel.

(2) Titanium alloy with large rebound after processing has the characteristics of small elastic modulus and large flexural strength ratio. During the drilling process, the titanium alloy produces greater elastic deformation under the action of drilling force.When the processing is completed, the drilling force disappears, and the processed surface will produce greater rebound. This kind of rebound may cause the size of the processed parts to be too poor, affecting the assembly accuracy and performance of the parts.

(3) The tool is easy to wear. The coefficient of friction between the titanium alloy material and the drill bit material is greater than the coefficient of friction between carbon steel, and the cutting deformation coefficient of titanium alloy is much smaller than that of other metals. This means that the friction speed of titanium alloy chips along the cutting edge of the drill bit is high and the friction interface temperature is high.Under the dual action of high temperature and high friction, the cutting edge of the tool is easy to wear out or even break, increasing the processing cost and the frequency of tool replacement.

(4) The chips are easy to bond and not easy to discharge. Titanium alloy has a large chemical affinity. In the drilling environment of high temperature and high pressure, it is easy to bond with the tool material. The chips are squeezed into the groove of the drill bit and are not easy to discharge, forming a chip tumor.Chip tumors will not only affect the stability of the cutting process, causing fluctuations in cutting force, but also scratch the processed surface and reduce the surface quality of the parts.For example, when machining titanium alloy shell parts, 6-Φ3 holes are distributed on the curved surface of the outer circle of the rotary body, and the processed holes are at an angle to the center of the rotation of the part. When machining oblique holes, the tool is more likely to slip and drill obliquely. Stuck drilling, resulting in poor size, tool wear is also more serious.

2. Solution And Principle

(1) Reasonable tool materials When drilling titanium alloy, suitable tool materials should be selected. Cemented carbide materials that do not contain or contain less TiC are a better choice. Cobalt-containing or YG(K) cemented carbide tool materials can improve the strength and durability of the tool. This is because titanium alloys and TiC-containing cemented carbide may react chemically at high temperatures, affecting tool performance. The cobalt-containing or YG(K) cemented carbide can reduce the knife resistance of titanium alloy parts during drilling and processing, eliminate the deformation caused by the cutting force, and thereby improve the processing quality and tool life.

(2) Reasonable tool angle In order to prevent greater rebound from drilling, reduce drilling force, and control deformation of parts, the tool angle needs to be reasonably designed. Increasing the top angle and grinding the angle between the two edges to 135°-140° can increase the rigidity of the drill bit and reduce the vibration during drilling. Increasing the rear angle at the outer edge of the drill bit to 12°-15° can reduce the friction between the drill bit and the machined surface and reduce the cutting heat. Trimming the length of the horizontal blade to 0.08-0.1 can reduce the axial force of drilling and make the drilling process more stable.

(3) A reasonable tool structure adopts a four-point drill bit, which can change the cross-section form of the drill bit and increase the cross-section moment of inertia, thereby improving the rigidity of the drill bit.When processing titanium alloy shell parts, the friction between the drill bit and the processed shell is large, and the drill bit with insufficient rigidity is easy to break. By optimizing the structure of the four-hole drill bit, the risk of the drill bit breaking is reduced, and the stability and reliability of the processing are improved.

(4) Reasonable drilling dosage According to the size of the drilling diameter, it is essential to choose a reasonable drilling dosage. For Φ3 drilling of shell parts, the diameter of the drill bit is small, and the spindle speed is too low, which will affect the roughness of the surface processing of the parts, while the feed is too large, it is easy to make the drill bit stuck and chipping. Therefore, it is necessary to determine the best combination of spindle speed and feed through experiments and practical experience to reduce the cutting heat of drilling, reduce tool wear, control part deformation, and ensure drilling quality.

(5) Reasonable injection method When drilling titanium alloy, water-based cutting fluid should not be used. Because water will form steam bubbles attached to the cutting edge at high temperatures, it will cause chip tumors in the machining drill bit, which will make the cutting unstable. The cutting fluid should be N32 mechanical plus kerosene, the ratio is 3:1 or 3:2, and vulcanized cutting oil can also be used. These cutting fluids have good lubricity and cooling properties, which can effectively reduce the friction between the tool and the workpiece, reduce the cutting temperature, and prevent chip bonding.

3. Example Application

When machining titanium alloy 6-Φ3 (mm) holes, cobalt-titanium alloy drill bits are selected, and the sharpening angle of the drill bits is reasonably selected.The specific parameters are as follows:

1) Increase the top angle of the drill bit to 2Φ= 135°-140° to increase the rigidity of the drill bit and reduce vibration and deformation during drilling.

2) Increase the rear angle of the edge of the drill bit to af=12°-15°, reduce the friction between the drill bit and the processed surface, reduce cutting heat, and improve the surface quality of the parts.

3) Increase the spiral angle to β=35°-40°, increase the feed force, make the chips easier to discharge, and reduce the accumulation of chips in the groove of the drill bit.

4) Increase the thickness of the drill core to d0 = (0.4-0.22)D to improve the sharpness of the drill bit and enhance the anti-breaking ability of the drill bit.

The grinding horizontal edge adopts an S-shaped or X-shaped shape to form a second cutting edge, which plays a role in chip splitting and makes the cutting process more stable.

In order to ensure the straightness of the holes of the parts processed by the drill bit, strictly control the amount of runout of the cutting edge of the drill bit to the axis line, which should not be greater than 0.03-0.1mm. Due to the small holes in the processed parts, a large speed is used to improve the surface processing quality of the parts, and a small feed is used to prevent the parts from getting stuck and chipping.Through practical experience, it is concluded that different drill diameters match different spindle speeds and feed rates.

In order to prevent the drill bit from drilling the holes processed on the bevel obliquely, first use a milling cutter with a diameter of less than Φ3mm to mill a small plane on the bevel to prevent the drill bit from drifting and tilting during drilling.Then use the Φ2mm center to drill the center of the 6-Φ3mm hole to ensure that the drill bit has the correct position when drilling.Then use a Φ3mm diameter drill bit to process the 6-Φ3mm hole of the part to the required size.

In order to reduce the cutting temperature during drilling, improve the surface roughness of parts processing, take away the chips accumulated in the holes of parts in time, and prevent the titanium alloy material from chemically reacting at high temperatures, causing the processed surface to harden by cold work, the electrolyte is selected as the cutting fluid for titanium alloy drilling. The composition is probably sunflower acid 7%-10%, triethanolamine 7%-10%, glycerol 7%-10%, boric acid 7%-10%, sodium nitrite 3%-5%, and the rest is water. You can also choose No. 32 mechanical oil plus kerosene.