α-Type Titanium Alloy TA4: The Wide Application And Future Prospects Of High-Performance Materials

α-Type Titanium Alloy TA4: The Wide Application And Future Prospects Of High-Performance Materials

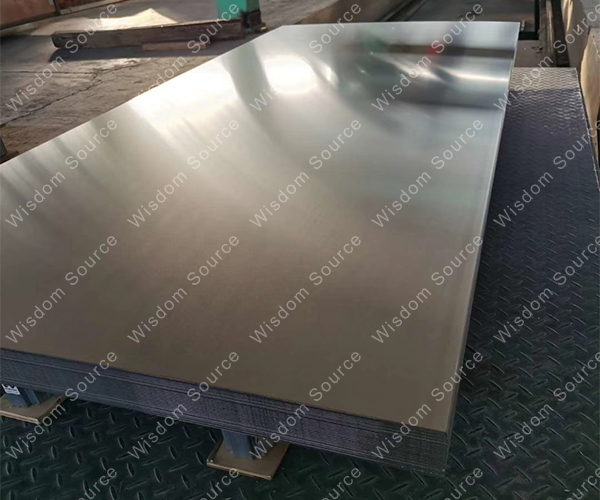

TA4, as a high-quality α-titanium alloy, plays an important role in many industrial fields due to its excellent high temperature strength, corrosion resistance and lightweight characteristics. Compared with industrial pure titanium, the tensile strength of TA4 has been improved, so it is more suitable as a structural material in the medium strength range. In China, TA4 titanium alloy is mainly used as welding wire, and its diverse product specifications meet different application needs, from fine filaments with a diameter of 0.1mm to thick filaments with a diameter of 6mm, which can be customized according to customer needs.

Excellent Performance Of TA4 Titanium Alloy

The density of TA4 titanium alloy is only 4.43g/cm3, which is about half the density of steel, which makes it an ideal lightweight material. In addition to its lightweight characteristics, TA4 also has excellent corrosion resistance and can maintain good corrosion resistance in a variety of media, including oxidizing, neutral and reducing media.

In terms of mechanical properties, TA4 titanium alloy exhibits high strength, high toughness and good fatigue resistance. Its tensile strength can exceed 1100Mpa, which belongs to the category of high-strength alloys.At the same time, TA4 also has good ductility and toughness, and can maintain stable mechanical properties in high temperature environments. In addition, it also has excellent creep resistance and stress relaxation resistance, and is suitable for working conditions in high temperature and high stress environments.

Wide Application Of TA4 Titanium Alloy

The wide application of TA4 titanium alloy benefits from its excellent performance and processability. In the aerospace field, TA4 is used in the manufacture of aircraft structural parts, engine parts and aerospace equipment, which provides strong support for the lightweight and high performance of aircraft. In the field of shipbuilding, it also plays an important role in the manufacture of hull structural parts and ship equipment, which improves the durability and safety of ships.

In the chemical industry, TA4 titanium alloy is widely used in the manufacture of chemical equipment, storage tanks and reactors. Its corrosion resistance enables the equipment to operate stably in harsh chemical environments. In addition, in the field of medical devices, TA4 is also used in the manufacture of artificial joints, dental implants and surgical instruments, making important contributions to the development of the medical field.

Future Prospects Of TA4 Titanium Alloy

With the continuous progress of science and technology and the continuous growth of application demand, the application field of TA4 titanium alloy will be further expanded. In the fields of aerospace, shipbuilding, chemical industry and medical equipment, TA4 titanium alloy will continue to play its important role and provide strong support for the development of related industries. At the same time, with the in-depth research of materials science and technological innovation, the performance of TA4 titanium alloy will be further improved to meet more complex and demanding application needs.

We believe that in the near future, TA4 titanium alloy will play a more important role in more fields, bringing more convenience and benefits to human production and life. As a representative of high-performance metal materials, TA4 titanium alloy will continue to lead the development trend of materials science and make greater contributions to the progress and prosperity of society.