Titanium Alloy Wire Bracket: Focus On Three High-End Application Areas

Titanium Alloy Wire Bracket: Focus On Three High-End Application Areas

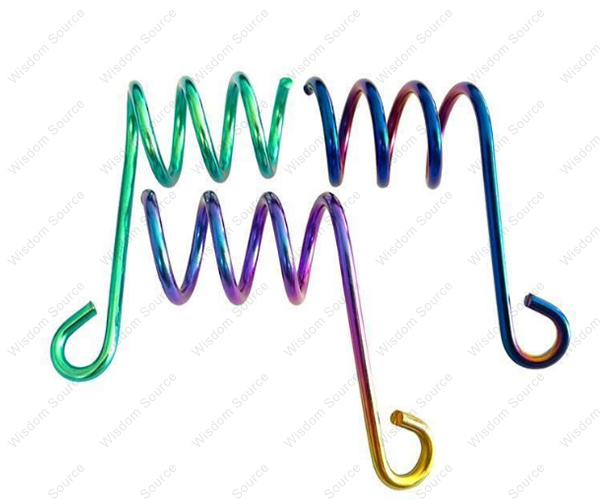

Titanium alloy wire bracket is a special structural part made of high-performance titanium alloy material, which is mainly used to fix, support and guide wires or cables. With the unique physical and chemical properties of titanium alloy, it stands out in specific fields where material properties are extremely demanding and has become the material of choice.

Its core functions are:

1. Precise Fixation And Support:

ensure that the wires are firmly installed in the designated position in accordance with the design requirements, effectively prevent sagging and shaking, and maintain line regularity.

2. Resist Environmental Impact:

reduce the damage to the wire caused by external factors such as wind swing and mechanical impact.

3. Basic Insulation Protection (under special design):

Although the titanium alloy itself conducts electricity, it can provide the necessary insulation protection on specific occasions through surface coating or special structural design.

4. Excellent Corrosion Resistance And Long Life:

The dense oxide film naturally formed on the surface of titanium alloy gives it excellent stability and long service life in harsh environments (such as high humidity, salt spray, and chemical environments).

The core advantages of titanium alloy (high strength, light weight, corrosion resistance, high temperature resistance, and good biocompatibility) make its wire bracket irreplaceable in the following three key fields. Application value:

1. Aerospace Field:

Application core: internal electrical systems of aircraft and spacecraft.

The advantages of titanium alloy are reflected: the extremely high strength-to-weight ratio (lightweight) significantly reduces the load on the aircraft; the excellent high temperature resistance ensures the safety of the line in high-temperature areas such as the engine compartment; and the excellent corrosion resistance responds to the complex environment at high altitude. Together, these characteristics ensure the ultimate safety and reliability of critical electrical systems.

2. High-End Medical Equipment Field:

Application core: precision diagnostic equipment (such as MRI, CT), treatment equipment, implantable equipment related circuits.

The advantages of titanium alloy are reflected: its excellent biocompatibility makes it suitable for human contact or implantation environment to avoid rejection; its excellent corrosion resistance is resistant to disinfectants and body fluid erosion; the high strength and stability of the material ensure the long-lasting reliability of precision electrical connections.

3. High-Performance Electronics/Precision Instruments:

Application core: the pursuit of extreme lightweight, miniaturization, and high reliability of cutting-edge electronic equipment, precision instruments, and internal wiring of high-end consumer electronics products.

The advantages of titanium alloy are reflected: its lightweight and high-strength characteristics contribute to equipment weight loss and space optimization; its excellent mechanical properties provide stable support; its good corrosion resistance enhances the durability of equipment under complex working conditions; its unique metallic texture can also meet the needs of high-end products for aesthetic design.

Titanium alloy wire bracket is by no means an ordinary bracket. It is a high-performance solution that combines high strength, lightweight, excellent corrosion resistance and special functions (such as biocompatibility). Its application core focuses on the three cutting-edge fields of aerospace, high-end medical equipment, and high-performance electronics/precision instruments that have extreme requirements for material properties. It is an important support element to ensure the safe, reliable and long-lasting operation of these key systems.