Analysis Of The Polishing Process Of Titanium Alloy

Analysis Of The Polishing Process Of Titanium Alloy

In recent years, with people's pursuit of high-quality life, titanium daily necessities have gradually entered people's lives. These daily necessities include titanium jewelry, titanium tags, titanium chopsticks, titanium spoons, titanium cups, etc. They are not only practical, but also have a unique charm. The surface of titanium alloy is smooth and bright, pearlescent, showing a noble texture, which is more attractive to people's eyes. So, how can titanium be made to shine brightly? This has to mention the polishing process.

Polishing is an ancient craft, and it is often used in the processing of jade and other jewelry products. People often say “three-point carving, seven-point grinding”, where "grinding" refers to polishing. For the polishing of titanium alloy, it is generally divided into two types: coarse polishing and fine polishing. In the processing process of titanium products, it is inevitable that burrs, scratches, edges and corners, stains, oil marks and other problems will occur. In order to solve these problems, two kinds of equipment, drum grinding and oscillating grinding, need to be used.

The principle of drum grinding is similar to that of drum washing machines. It usually uses emery or diamond sand and a small amount of water for grinding and polishing. This polishing method is suitable for jewelry items that are small in size and inconvenient to polish, such as earrings, tags, etc. The drum polishing machine can automatically rotate in both directions, and the timing can be set, the time range is 0-60 minutes.

Vibration polishing is a device that uses vibration force and the interaction between the abrasive and the workpiece to complete the polishing process. Vibration polishing is suitable for a variety of materials, including metals, ceramics, etc.It can efficiently remove scratches and deformed layers, reduce sample damage, and is suitable for the treatment of a variety of materials.

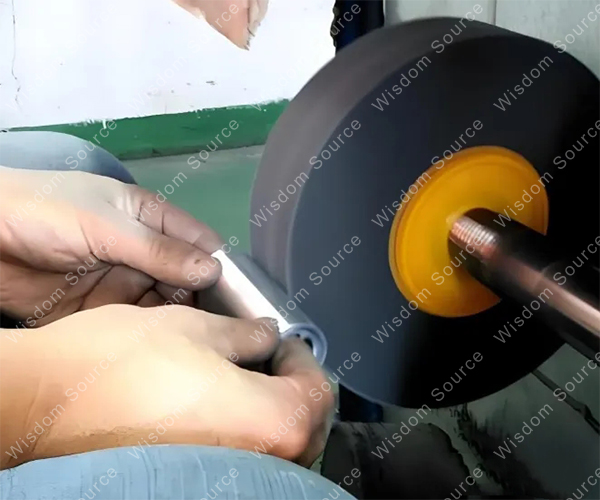

Generally speaking, after the rough throw is completed, the next step is the fine throw. For the different needs of customers, different cloth wheels or grinding wheels and polishing auxiliary materials, polishing waxes, can be used for polishing. Cloth wheel polishing is a commonly used polishing method. It uses the abrasive on the surface of the cloth wheel to polish and polish the surface of the workpiece by contacting the cloth wheel with the surface of the workpiece. Used with polishing consumables such as cloth wheels, brushes, flying saucers, polishing waxes, etc., The material and thickness of the cloth wheels are different, and can be used for different surface treatment needs. Through fine polishing, the needs of customers can basically be met.

The main purpose of titanium alloy polishing is to improve its surface quality and aesthetics, while also improving its surface corrosion resistance. Titanium alloy has been treated with polishing technology, the surface is smooth and bright, showing a unique charm, which satisfies people's pursuit of high-quality life.