Titanium Alloy 3D Printing: A new Chapter In Motorcycle Manufacturing

Titanium Alloy 3D Printing: A new Chapter In Motorcycle Manufacturing

Do you remember the amazement of everyone when 3D printing technology first appeared in the arena?“This technology is so cool, right? In the future, we can print out all the things we want by ourselves!” Now, such a future seems to have quietly come. You may already have a few small 3D-printed objects in your home, such as camera brackets, bicycle gaskets, etc. But when we talk about some more "hardcore” things, such as motorcycle parts, what about the situation?

In fact, this is not an unattainable dream. As the future of electric motorcycles becomes clearer, some manufacturers have begun to integrate 3D printing technology into their manufacturing processes. And Stark Future is one of the forerunners in this field. They focus on the production of high-performance Varg electric off-road motorcycles, and hope to revolutionize the traditional way of motorcycle manufacturing through 3D printing technology.

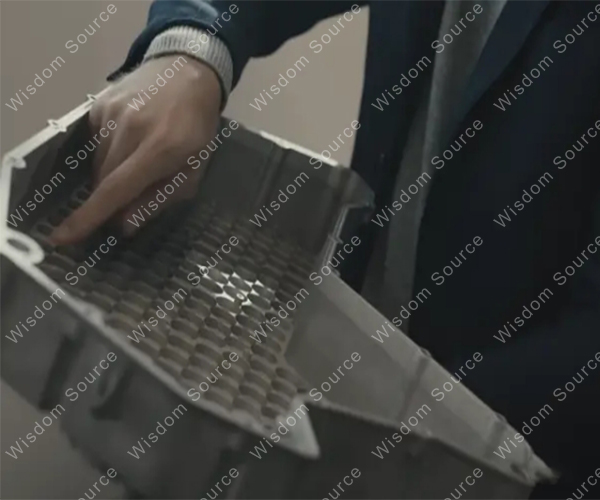

Stark Future has established a close strategic cooperative relationship with Farsoon Technologies, a professional industrial 3D printing company. Farsoon's 3D printing technology is by no means comparable to the small machine in your basement. These industrial-grade 3D printing equipment can produce parts with extremely complex shapes and structures that cannot be achieved by traditional manufacturing methods.

In particular, Stark Future is now aiming at the large-scale metal powder bed fusion technology, namely titanium 3D printing. Their CEO Anton Wass firmly believes that titanium 3D printing can not only make high-performance parts more accessible, but also significantly shorten production time." Stark firmly believes that the large-scale production of titanium 3D printing is the inevitable way to build a better motorcycle.” He said so.

Stark Future's main investment equipment is Farsoon's FS721M-H-8-CAMS large metal 3D printing system. The overall size of this machine has reached an astonishing 750 x 420 x 650 mm (about 29 x 16 x 26 inches), which can produce quite large parts. Although it is not yet possible to print out the entire motorcycle directly, I believe it is only a matter of time.

In fact, 3D printing technology in high-performance applications is no longer new. In F1 racing cars, MotoGP factory cars, and even NASA space missions, we can find 3D printed parts. Therefore, 3D printing is rapidly becoming the mainstream production method.

Thinking of 3D-printed titanium alloy parts on motorcycles, you might think it's a bit crazy. But rest assured, these components have undergone the most stringent environmental tests. The future has arrived. If these new technologies can allow us to ride cooler and more fun motorcycles, then why not?