Uncirculated Manufacturing Of Titanium Alloy Powder Attracted Attention At The North American Exhibition

Un-circulated Manufacturing Of Titanium Alloy Powder Attracted Attention At The North American Exhibition

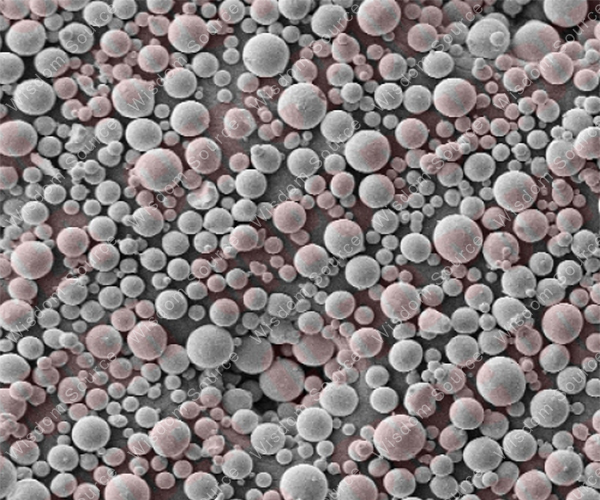

At the RAPID+TCT 2024 exhibition held at the Los Angeles Convention and Exhibition Center from June 25 to 27, 2024, the booth of CNPC POWDER Booth No. 2231 has become the focus of attention of many exhibitors. This leading domestic 3D printing metal powder manufacturer not only demonstrated a variety of its industry-leading products, but also achieved remarkable results in the innovation of titanium alloy materials, which has brought new inspiration to the global additive manufacturing industry.

The Green Revolution Of Circulating Titanium Alloy Powder

The circulating titanium alloy powder on display this time is a major innovation in the field of titanium alloy materials. In view of the high cost of titanium alloy powder, the company has not only successfully reduced production costs by introducing a waste recycling powder manufacturing process, but also achieved the basic consistency between the performance of titanium alloy recycled materials and the original powder. This innovative technology not only reduces production costs, but also takes a solid step in environmental protection. Recycled titanium alloy powder has the characteristics of being green and recyclable, which means that the waste generated in the 3D printing process can be effectively recycled and utilized, thereby reducing the dependence on natural resources. The emergence of this material provides a green and recyclable alternative to traditional titanium alloy powders, which is of great significance to promote the application of 3D printing technology in many fields such as military industry, aerospace, and consumer electronics.

In September 2023, it became the first 3D printing metal powder manufacturer in the domestic industry to obtain SCS certification for 100% titanium alloy recycled materials. This certification not only proves the environmental protection and sustainability of Zhongti new materials in the production process of circulating titanium alloy powder, but also demonstrates its leading position in the industry.

The carbon emissions of the circulating titanium alloy powder production process are only 10% of that of the traditional EIGA production process. This data undoubtedly sets a new environmental benchmark for the global additive manufacturing industry, and it also shows the world the determination and strength of Chinese companies in green manufacturing.

Far-Reaching International Influence

The wonderful performance at the RAPID+TCT 2024 exhibition not only attracted the attention of many domestic and foreign exhibitors, but also had a profound impact internationally. Circulating titanium alloy powder technology has not only brought new development opportunities to the global additive manufacturing industry, but also made an important contribution to promoting the development of the global manufacturing industry in a green, low-carbon and sustainable direction.