The “Material Star” In The Aerospace Industry: Why Does TB5 Titanium Alloy Become The Key Choice?

The “Material Star” In The Aerospace Industry: Why Does TB5 Titanium Alloy Become The Key Choice?

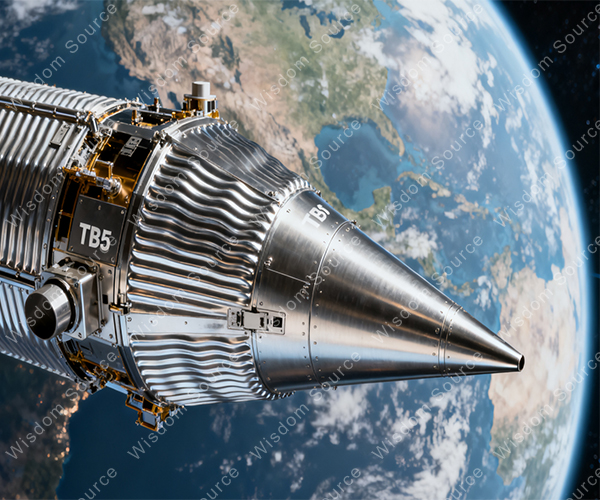

Between the vast blue sky and the deep space, every breakthrough in aircraft is inseparable from the innovation of material technology. There is a metal material that has become the “sweet potato” in the aerospace field with its hard-core strength of light weight, high strength, and resistance to extreme environments. It is TB5 titanium alloy (Ti-15V-3Cr-3Sn-3Al). From the key structure of the fighter to the core components of the satellite, its figure is everywhere, silently guarding every flight and exploration.

1. Lightweight And High Strength Coexist, Unlocking A New Level Of Flight Efficiency

For aerospace equipment, “weight loss” and “toughness” are like two sides of a coin, and they are indispensable. TB5 titanium alloy perfectly balances these two major needs. Its density is only 4.48g/cm3, which is equivalent to 60% of steel, but it can explode after aging treatment. The tensile strength of 1200-1400MPa, the specific strength is much higher than that of traditional aluminum alloys and steel.

Taking the umbrella beam structure of a fighter aircraft as an example, after replacing the traditional 30CrMnSiA steel with TB5 titanium alloy, the weight was successfully reduced by 28.6% (about 1.13kg). This seemingly insignificant weight reduction can significantly improve the fuel efficiency of the aircraft, increase the payload, allow the fighter to carry more weapons and equipment, and allow the airliner to reduce operating costs and become an “invisible booster” to improve flight performance.

2. Cold Forming Talent Is Full, And Complex Parts Can Be Easily Handled

Parts in the aerospace field often have complex shapes and extremely high accuracy requirements, which is a huge test for the processing performance of materials. As a metastable β-type titanium alloy, TB5 titanium alloy has excellent cold forming ability in the solid solution state, and the cold-rolled deformation can reach more than 90%. Whether it is complex sheet metal parts (such as resistance umbrella beams) or cold-heading rivets, bolts and other fasteners, it can be easily competent.

Compared with traditional α+β titanium alloys (such as TC4), TB5 titanium alloys can be formed with high precision without intermediate annealing during processing, which not only simplifies the production process and improves efficiency, but also ensures the stability of part quality, which perfectly matches the stringent requirements of precision parts in the aerospace field.

3. The "Guardian” Of Extreme Environments, Full Of Durability

During the flight of aircraft, they have to face the challenges of high altitude, high temperature, ocean salt spray and other harsh environments, and TB5 titanium alloy is the “hard-core guard” to meet these challenges. It can maintain stable performance in a high temperature environment of 300-600℃, and is an ideal material for manufacturing hot-end components of aviation engines to ensure reliable operation of the engine under high temperature and pressure and extend its service life.

At the same time, the oxide film formed on its surface has excellent corrosion resistance and can effectively resist the erosion of seawater and chlorides. It is especially suitable for carrier-based aircraft and aerospace equipment in the marine environment, greatly reducing the corrosion loss and maintenance costs of equipment.

4. Adapted To The Whole Scene, It Can Be Called An Aerospace "All-Rounder”

The application range of TB5 titanium alloy covers almost the core fields of aerospace, and it can be called an "all-around player”.:

1) In The Field Of Structural Parts: replace steel to make fuselage frames and wing girders, and reduce weight by more than 40%, which not only improves flight performance, but also reduces the risk of structural fatigue;

2) Fastener Field: the rivets and bolts manufactured have both high strength and fatigue resistance, and are widely used in B1B bombers, Boeing airliners, etc. to protect structural safety;

3) Engine Components Field: used for key components such as compressor blades and turbine discs to improve the thrust-to-weight ratio of the engine and enhance the reliability under extreme operating conditions;

4) In The Field Of Satellite Components: satellite corrugated plates, support cones, etc. are manufactured through blow molding technology to achieve lightweight design and create possibilities for satellites to carry more scientific instruments.

5. Excellent Economy And Compatibility, Ideal For Mass Production

In addition to its outstanding performance, TB5 titanium alloy also has great advantages in terms of economy and process compatibility. It can flexibly adjust its performance through the “solution + aging” treatment to adapt to the needs of different components; it matches the potential of carbon fiber composite materials, which can effectively avoid galvanic corrosion and make the multi-material combination structure safer and more reliable.