Titanium Alloy Application: Ferrari GDI f154CB Engine Innovation Exploration

Titanium Alloy Application: Ferrari GDI f154CB Engine Innovation Exploration

Ferrari 488GTB, as the brand's first V8 turbocharged, mid-rear engine mass-produced coupe, its excellent performance has undoubtedly set a new benchmark for the automotive industry. Among them, the application of titanium alloy turbocharger has added a touch of legend to this red devil. This article will delve into the application of titanium alloy in the turbocharger of Ferrari GDI f154CB engine and the technological innovations it brings.

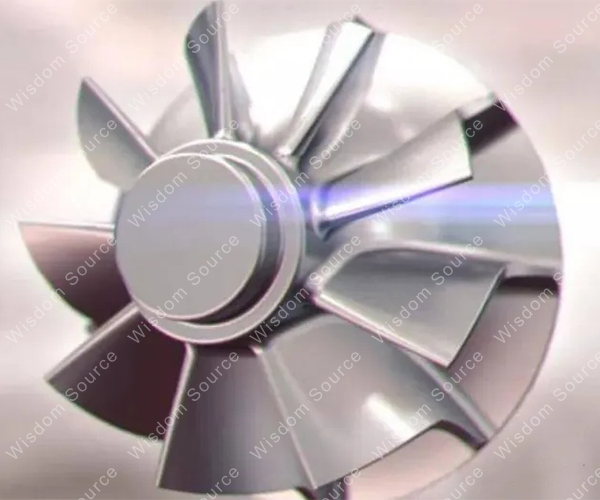

Structural Characteristics Of Titanium Alloy Turbocharger

The turbocharger of the Ferrari GDI f154CB engine uses innovative titanium alloy materials. Compared with traditional materials, titanium alloy has higher strength and lighter weight, which allows the turbocharger to maintain efficient performance while effectively reducing turbine hysteresis. In addition, the new IHI compressor turbine design is larger than in the past, and its dual eddy current design can optimize the peak pressure of the turbine exhaust under all engine speed conditions, further improving engine performance.

Advantages Of Dual Eddy Current Turbines

The design of the dual eddy current turbine brings two major advantages to the Ferrari GDI f154CB engine.First of all, due to the ignition sequence and the characteristics of the flat crankshaft, each exhaust cycle will not affect the subsequent cycles of the same cylinder group, thus ensuring the smooth operation of the engine.

Secondly, the use of two smaller volumes to release the same density of gas can produce a Venturi effect, increase energy and maximize air pressure, and further increase the power output of the engine.

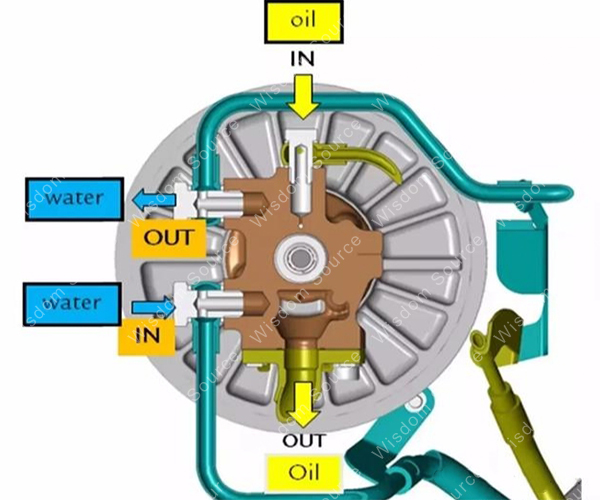

Lubrication And Cooling Of Turbo-compressors

In the design of titanium alloy turbochargers, lubrication and cooling systems are also essential. In order to ensure the efficient operation of the turbine under extreme conditions, Ferrari engineers designed advanced lubrication and cooling systems for the turbo compressor. When the engine is turned off or idling, the electronic pump provides water circulation to avoid overheating of the turbine. At the same time, the cooling fan of the inter-cooler will also start under certain conditions to ensure the stable operation of the turbine in a high temperature environment.

Exhaust Gas Drain Valve And Booster Adjustment

The exhaust gas drain valve plays a key role in the control of the turbocharger. In the Ferrari GDI f154CB engine, the valve is normally open and controlled by a variable PWM power supply to ensure better heating of the catalytic converter during cold start. At the same time, the booster adjustment system focuses on the downstream of the compressor by finely adjusting the calculation of mass density to achieve precise control of the target torque value.The application of titanium alloy in the turbocharger of the Ferrari GDI f154CB engine undoubtedly adds more technological content and competitive advantages to this legendary engine. Its unique structural characteristics, the design advantages of dual eddy current turbines, advanced lubrication and cooling systems, and precise exhaust gas drain valves and booster adjustment systems together provide a strong guarantee for the excellent performance of Ferrari 488GTB. This generation of legendary engine technology of the Red Devil will undoubtedly continue to lead the trend of the automotive industry.