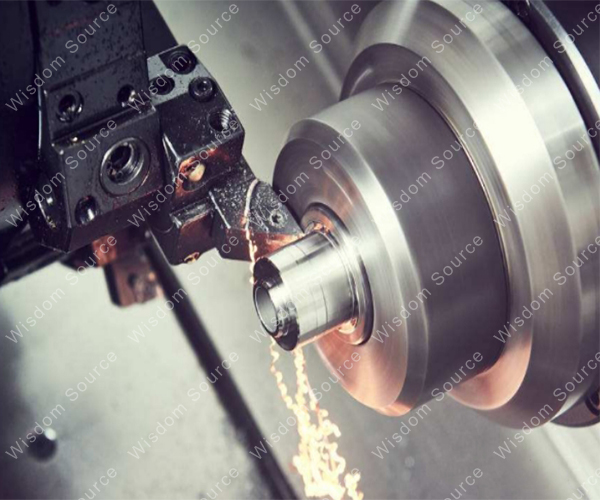

Research On Titanium Alloy Thread Processing Technology

Research On Titanium Alloy Thread Processing Technology

In many fields such as aerospace and

chemical industry, titanium alloys have been widely used because of their

excellent properties. However, the unique processing characteristics of

titanium alloy have brought certain challenges to its thread processing. In-depth

exploration of the processing characteristics of titanium alloy, tool selection

and pipe joint thread processing technology is of great significance to improve

the quality of titanium alloy thread processing and improve production

efficiency.

1. Processing Characteristics And Characteristics Of Titanium Alloy

1) Low Thermal Conductivity

Titanium alloy has poor thermal

conductivity, which directly leads to poor heat dissipation. During thread

processing operations, it is difficult to effectively diverge and cool the

heat, and the temperature of the processing site rises rapidly. After

processing, due to the accumulation of heat, the material has a large amount of

rebound, which can easily deform, affecting the machining accuracy and part

quality. At the same time, the high temperature environment has a serious

impact on the processing tool, and the wear of the tool edge is aggravated,

which greatly reduces the service life of the tool and increases the processing

cost.

2) Small Deformation Coefficient

The small deformation coefficient of

titanium alloy is characteristic, which makes the cutting force distribution of

the tool during the processing process uneven, and the tool loss increases. During

the cutting process of the tool, the force per unit area is increased, which

leads to faster tool wear and requires more frequent tool replacement, which

affects the continuity and efficiency of production.

3) High Chemical Activity

Titanium alloy has strong chemical activity, and it is easy to react chemically with other metal materials under the condition of high temperature during processing. This reaction will cause the adhesion between the tool and the tap and the processed material, resulting in the phenomenon of “biting the knife”. Biting the knife” will not only cause damage to the tool, affect the normal progress of processing, but also reduce the surface quality of thread processing and increase the difficulty of subsequent processing.

4) Excellent Overall Performance

In order to enhance the strength of

titanium metal elements, alloying elements are added to pure titanium to form

titanium alloys. Titanium alloys are mainly divided into three types: titanium

alloys represented by TA, titanium alloys represented by TB, and +titanium

alloys represented by TC. Among them, +titanium alloy is a duplex alloy and is

widely used. It is an important titanium alloy raw material in the aviation

industry. Titanium alloy has many good metal properties: high strength, low

density, but far stronger than many alloy steels; good heat resistance, heat

resistance is hundreds of times higher than aluminum alloy, with good thermal

stability; excellent low temperature performance, can still maintain good

performance under ultra-low temperature conditions; strong corrosion

resistance, strong resistance to acids, alkalis, moisture, chlorides, etc.;

However, its chemical activity is large, it can react with oxygen, nitrogen,

carbon and other chemical elements in the air, and its thermal conductivity is

low, and its thermal conductivity is much lower than that of iron, aluminum and

other metals.

Tests by Baoji Titanium Industry Research

Institute have shown that there are certain differences in the performance

indicators of titanium alloys with different composition proportions, which

further highlights the importance of in-depth understanding of the processing

characteristics of titanium alloys.

2. Selection Of Thread Processing Tools For Titanium Alloy

1) The Advantages Of Wrong-Tooth Taps

Titanium alloy thread processing mostly

uses wrong-tooth taps for tapping operations. The design of the wrong-tooth

taps is unique, and the knife teeth of the taps are removed one at each

interval, and they are arranged in staggered patterns. This structure enables

the processed parts and the taps to have only one-sided contact, which

effectively reduces the friction between each other and reduces the torque

generated by the friction. In this way, the tap can be effectively prevented

from being stuck or damaged, thereby improving the quality of thread

processing.

When using wrong-tooth taps, the cutting

thickness is doubled and the depth is greater than the cold-work hardened

layer. Although the increase in cutting thickness will lead to an increase in

the cutting force of the tap teeth, it is more advantageous for cutting chip

removal, the friction force is reduced, and the adhesion of the tap and the

chips is reduced, thereby improving the durability and thread accuracy of the

tap. In terms of the design of the wrong-tooth tap, the number of completed

cogs should be odd, which can reduce the force on the tooth edge and extend the

service life of the tap. In the threading of titanium alloy materials, the use

of wrong-tooth taps can maintain the stability of tapping and improve the

threading accuracy.

2) The Cooperation Between High-Speed Steel

Wire Taps And Cemented Carbide Taps

For the threading of titanium alloy

materials, it is recommended to use high-speed steel wire cones. The high-speed

steel wire cone has the characteristics of high toughness, deformation

resistance and good wear resistance. In the tapping process, a high-speed steel

wire cone can be used for preliminary tapping to complete most of the cutting

work. After the initial tapping, the screw hole is corrected with a cemented

carbide tap. Cemented carbide taps have high hardness and strong wear

resistance, which can further ensure the accuracy and quality of the thread. With

the continuous deepening of tool material research, it is expected that tap

materials that are more suitable for titanium alloy thread processing will

appear in the future.

3. Processing Technology Of Titanium Alloy Pipe Joint Thread

Increasing the threaded bottom hole can effectively reduce the cutting force and heat generated during processing. Due to the large strength of titanium alloy pipes, when increasing the diameter of the threaded bottom hole, it is necessary to fully consider the requirements for the thread contact rate and the specific number of thread heads. Under the premise of ensuring the threaded connection performance, the amount of increase in the diameter of the bottom hole is reasonably determined. From the perspective of processing technology, appropriately increasing the thread inner diameter requirements can reduce the thread tooth height. Appropriately increase the thread diameter, which is particularly suitable for tapping special materials such as titanium alloys. Although this will reduce the thread contact rate, the thread connection is still stable and reliable due to the increase in thread length.

2) Selection Of Machine Tool Tapping Process

In order to prevent the tap from breaking

due to excessive pressure during processing, the processing technology of

machine tapping can be selected. The tapping of the machine tool has the

advantages of high stability and accurate pressure control, which can ensure

uniform tap force during the tapping process and reduce the risk of tap

breaking. Through the precise control of the machine tool, the quality and

consistency of thread processing can be improved, and the high-precision

requirements of titanium alloy pipe joint threads can be met.

Titanium alloy thread processing needs to fully consider its unique processing characteristics, and reasonably choose processing tools and processing techniques. Through the use of wrong-tooth taps, high-speed steel wire taps and cemented carbide taps in combination, as well as the optimization of thread bottom hole processing and the use of machine tool tapping technology and other measures, the quality and efficiency of titanium alloy thread processing can be effectively improved, and it provides a strong guarantee for the wide application of titanium alloy in various fields.