A Revolutionary Breakthrough In The Processing Of Titanium Alloy Dentures!

A Revolutionary Breakthrough In The Processing Of Titanium Alloy Dentures!

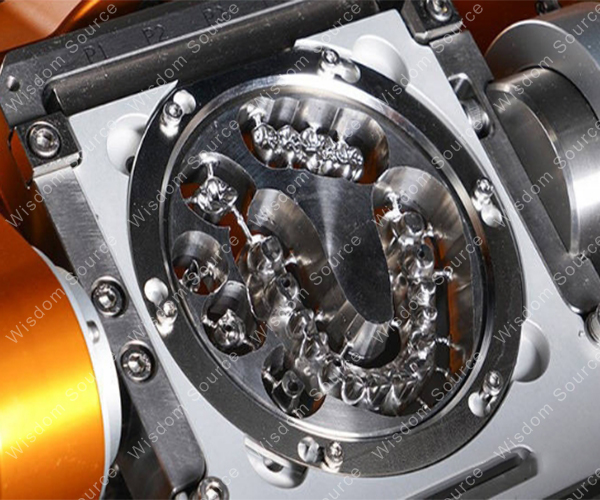

Are you still troubled by the low processing efficiency and poor accuracy of titanium alloy dentures? The spindle of the German SycoTec DS45 DC tooth carving machine relies on cutting-edge technology to bring you an efficient, accurate and stable processing experience, and completely solve the pain points of the industry!

Core Advantage:

1. Ultra-high speed at 80,000 rpm, easy to control with titanium alloy

2. The maximum speed is 80,000 rpm, with 1370W high-power output, titanium alloy processing is easy, and the efficiency is significantly improved!

3. 12.4 Ncm strong torque, more stable processing

4. The high torque output effectively suppresses vibration, ensures stability under high-speed operation, has smaller errors and higher yields!

5. ≤1µm cone beating, micron-level accuracy

6. The precision technology achieves ultra-high precision, the complex denture structure can also be perfectly presented, and the fit is impeccable!

7. Pneumatic automatic tool change, efficiency upgrade

8. The quick tool change design greatly reduces downtime and further improves production efficiency!

9. Lightweight design (1.85kg), flexible operation and labor-saving

10. Long-term use is burden-free, and processing is easier!

11. German quality, reliable and durable

12. Strictly selected materials and advanced technology ensure long-term stable operation and reduce maintenance costs!

Application Area:

1. Denture processing (Zirconia, Titanium Alloy, CAD/CAM)

2. Industrial robots (metal/composite material processing)

3. PCB sub-board (aluminum substrate, copper substrate cutting)

4. Transformation of CNC machine tools (efficiency improvement)

5. Advertising industry (non-metallic/flexible material processing)

6. Ceramic ferrule (internal and external grinding)

7. Micro-porous processing

8. Provide complete solutions for high-speed spindles & robots for the global industrial field!