Titanium Alloy: The Key Material For Future Energy Technology

Titanium Alloy: The Key Material For Future Energy Technology

Under the dual challenges of climate change and energy transformation, human exploration of clean energy technologies has never stopped. In this revolution, titanium alloy, with its unique material properties, is becoming an important bridge connecting traditional energy and new energy technologies. This article will objectively analyze the practical application value of titanium alloy in the energy field and its technological development status.

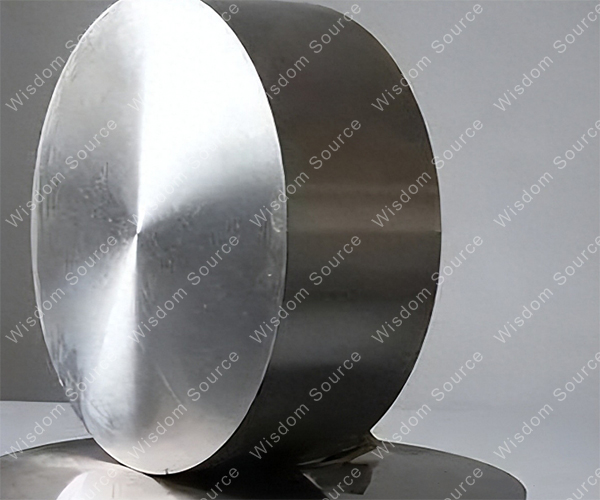

1. The Core Advantages Of Titanium Alloy

1) Lightweight and High Strength: the density is 4.5g/cm3 (57% of steel), and the specific strength reaches 29MPa·m3/kg

2) Environmental Tolerance: In the seawater environment, the corrosion rate is <0.001mm, and it is resistant to acid-base media with a pH value of 0.5-13.

3) Thermal Stability: Conventional industrial titanium alloys (such as Ti-6Al-4V) can have an operating temperature of up to 450℃

4) Hydrogen Compatibility: Specific titanium alloys can store hydrogen equivalent to 800-1000 times their own volume

2. Typical Application Scenarios And Technical Progress

1) Nuclear Energy Safety Field

In the third-generation pressurized water reactor nuclear power plant, the condenser tube bundle made of Ti-3Al-2.5V alloy has been commercialized. The service life of this material in boron-containing high-temperature water environment can reach 40 years, which is more than 3 times longer than traditional copper alloys. The actual operating data of a domestic nuclear power plant show that the titanium alloy cooling system reduces the annual maintenance cost by 27%.

2) Solar Energy Utilization System

In photovoltaic power plants, the Gr12 titanium alloy bracket system (Ti-0.3 Mo-0.8Ni) has been continuously used in the Salt Lake area of Qinghai for 8 years, and its resistance to wind and sand erosion is 5 times that of aluminum alloy. In the field of solar thermal power generation, titanium-plated ceramic composite heat-absorbing pipes can increase the operating temperature to 580℃, and the thermal efficiency reaches 68%.

3) Hydrogen Energy Industry Chain

In the hydrogen production process of electrolytic water, the service life of industrial-grade titanium anode (Ti/RuO₂-IrO₂) in an alkaline electrolytic cell exceeds 30,000 hours. In terms of storage and transportation, the hydrogen storage capacity of the TiFe hydrogen storage alloy reaches 1.8wt%. With carbon fiber reinforced technology, a mobile hydrogen storage device with a working pressure of <5MPa has been developed.

4) Marine Energy Development

A marine energy demonstration project adopts a wave energy conversion device made of Ti-631 alloy (Ti-6Al-3V-2Zr), which has been operating continuously in the harsh environment of the South China Sea for 4 years, with a structural integrity rate of 98%.Compared with stainless steel equipment, the all-titanium seawater pump system reduces energy consumption by 15% and extends the maintenance cycle to 5 years.

3. Rational Development Outlook

At present, the application of titanium alloys in the energy field is still facing the challenges of high cost (about 5-8 times that of stainless steel) and high processing difficulty. However, with the advancement of powder metallurgy technology and 3D printing technology, a domestic company has achieved a 40% reduction in the cost of titanium alloy components. According to the report of the International Energy Agency, the demand for titanium alloys in the energy sector will account for 35% of global titanium consumption by 2040, and the main growth points will be concentrated in the fields of hydrogen energy storage and transportation and nuclear fusion devices.

Judging from actual engineering cases, titanium alloy is changing from an "optional material" to a "required material" for specific scenarios. Its technical value is not to replace all traditional materials, but to provide irreplaceable solutions to key pain points in the energy transition. The rational application of this material may reshape the design logic of future energy equipment.