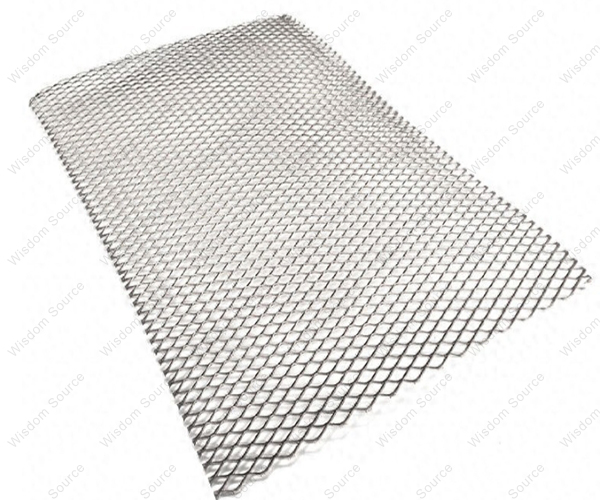

Titanium Mesh: Ideal Material For Multi-Field Filtration And Separation

Titanium Mesh: Ideal Material For Multi-Field Filtration And Separation

In the context of the rapid development of modern industry and science and technology, titanium mesh has become the core material in the fields of acid-base environment, high temperature and high pressure, and special media filtration and separation due to its excellent corrosion resistance, high strength and good bio-compatibility.

1. Diverse Materials, Suitable For Diverse Needs

The material of titanium mesh covers two categories: pure titanium and titanium alloy, and can be flexibly selected according to the use scenario:

1) Pure titanium series: GR1, GR2, GR3, known for its high purity (≥99.6%) and excellent corrosion resistance, suitable for extreme environments such as strong acids, alkalis, and seawater.

2) Titanium alloy series: TA8, TA9(GR7), TA10(GR12) (containing molybdenum, resistant to chloride ion corrosion), TC1 (aluminum-vanadium alloy, higher strength), TA8-1/TA9-1 (improved alloy), taking into account strength and corrosion resistance, suitable for high-load scenarios such as military industry and ships.

2. Rigorous Craftsmanship, Standards And Specifications

The production and testing of titanium mesh strictly follow the GB/T26059-2010 standard to ensure stable product performance:

1) Surface Treatment:

Black titanium mesh: The surface is coated with graphite emulsion coating to enhance lubricity, and it is suitable for deep processing scenarios such as stamping and stretching.

Bright titanium mesh: uncoated design, high surface finish, directly used in food, medicine and other fields with strict cleanliness requirements.

2) Weaving Process:

Plain weave mesh: stable structure, suitable for general filtration.

Twill woven mesh: higher density and better filtration accuracy.

Dense woven mesh: low porosity, suitable for the separation of ultrafine particles.

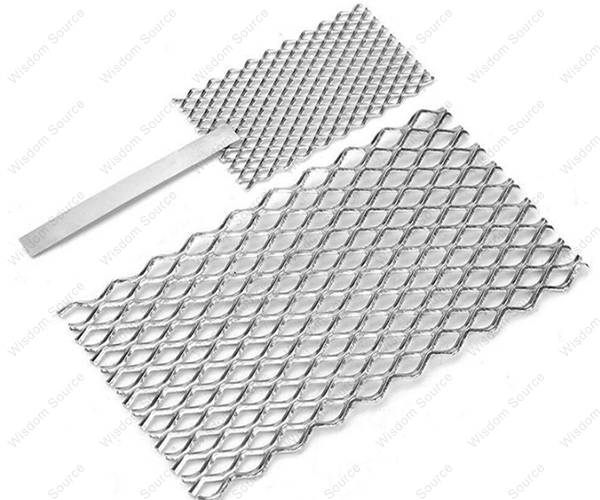

3. Product Marking: Precise Traceability And Selection

Titanium mesh adopts a standardized marking system and is marked in the order of ”product name-grade-status-specification-standard number".For example:

"Mesh board GR1 ZM 10×1000×2000-12.5×4.5×17”

Analysis: GR1 material, cold rolled and annealed state (ZM), mesh thickness 10mm, width 1000mm, length 2000mm, mesh size 12.5mm (length)×4.5mm (width)×17mm (depth).

This marking system facilitates users to quickly identify material performance and dimensional parameters, and optimize procurement and inventory management.

4. It Is Widely Used And Enables Multi-Industry Upgrading

The high temperature resistance and corrosion resistance of titanium mesh make it a cross-industry solution:

1) Chemical industry and environmental protection:

Acid-base solution filtration, catalyst carrier, and exhaust gas treatment replace traditional stainless steel mesh and extend the service life by 3-5 times.

2) Shipbuilding and military industry:

Seawater desalination filters, anti-corrosion parts of ships, and missile launchers are filtered to resist salt spray and high-pressure environments.

3) Energy and high temperature industry:

Electric furnace heat treatment support net (temperature resistance ≥600℃), petroleum cracking filter element, to ensure the stability of high temperature working conditions.

4) Food and medicine:

Bright titanium mesh is used for juice clarification and liquid filtration, which complies with FDA certification and avoids metal ion pollution.

5) Emerging areas:

Electromagnetic shielding network (5G base station), hydrogen energy storage, transportation and filtration, to help the landing of cutting-edge technologies.

With “corrosion resistance, light weight and high strength” as its core advantages, titanium mesh is extending from the traditional filtration field to high-end manufacturing and green energy. In the future, we will work with industrial chain partners to promote the standardization and intelligent development of titanium mesh, and provide key material support for global industrial upgrading.