Comprehensive And Detailed Introduction To Titanium Rod Specifications

Comprehensive And Detailed Introduction To Titanium Rod Specifications

1. Specification Classification and Size Range Of Titanium Rods

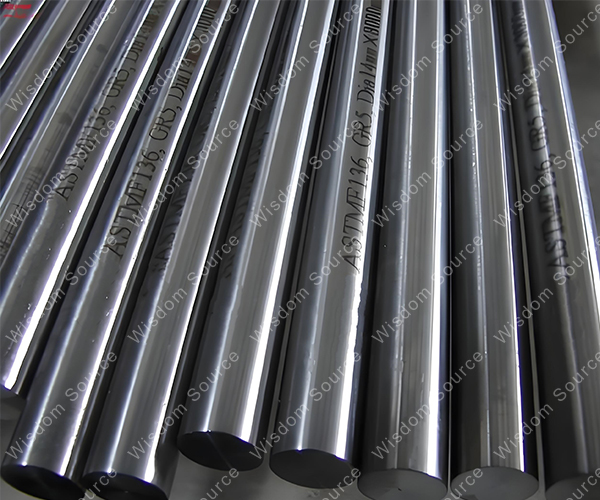

The specifications of titanium rods mainly cover two aspects: diameter and length. In terms of diameter, the choice of titanium rods is very wide, from an extremely tiny 0.5mm to an unusually large 400mm, which can meet the customized needs of customers. In terms of length, the standard titanium rod length is generally about 3000 mm, but it can also be cut or extended according to the specific needs of customers.

In addition, the surface treatment of titanium rods is also a part of the specification classification that cannot be ignored. Different treatment methods such as polishing, pickling, and optical rotation are designed to give titanium rods better surface quality and anti-corrosion properties. The choice of these processing methods also needs to be decided according to the specific application scenarios and needs of customers.

2. Application Areas And Characteristics Of Titanium Rods Of Different Specifications

Since their fine size and excellent electrical conductivity, these titanium rods are often used to make precision instruments and parts such as electrodes and cutting tools. At the same time, due to its good bio-compatibility, it is also widely used in the field of medical devices.

2) Titanium rods with a diameter between 10mm and 100mm:

This type of titanium rod is widely used in aerospace, shipbuilding, chemical industry and other industrial fields because of its durability and strong corrosion resistance.For example, they are often used to make important components such as axles, turbine engine blades, and marine propellers to ensure the stable operation and long-term use of equipment.

For their strong load-bearing capacity and corrosion resistance, these titanium rods are often used in the manufacture of nuclear power plant system equipment, heavy machinery and equipment and other fields with extremely high material requirements. They can withstand huge pressure and corrosive environments to ensure the long-term safe operation of equipment.

3. Manufacturing Process And Process Of Titanium Rod

1) The manufacturing process of titanium rod mainly includes investment casting, heat treatment, titanium rod processing and surface treatment. Among them, investment casting is the main process for making large-diameter titanium rods. By precisely controlling the size and shape of the investment mold, it can ensure that the titanium rods obtain good dimensional accuracy and surface quality during the casting process.

2) Heat treatment is to heat and cool the titanium rod to improve its internal organization and performance. The processing link includes cutting, grinding, drilling and other processes to meet the specific needs of customers for the shape and size of titanium rods.

3) Surface treatment is the key link to give titanium rods better surface quality and anti-corrosion properties. Through polishing, pickling, optical rotation and other treatment methods, impurities such as oxide skin and oil stains on the surface of the titanium rod can be removed, while improving its surface finish and anti-corrosion properties.

4. Precautions and Techniques For Purchasing Titanium Rods

When buying titanium rods, we need to pay attention to the following points:

1) Choose the appropriate titanium rod specifications according to the application scenarios and needs: different application scenarios and needs have different specifications for titanium rods. Therefore, when purchasing titanium rods, we need to fully understand customer needs and application scenarios in order to choose the appropriate titanium rod specifications.

2) Carefully check the surface quality of the titanium rod: the surface quality of the titanium rod directly affects its performance and life. Therefore, when purchasing, we need to carefully check the surface of the titanium rod for defects, cracks and other defects to ensure its reliable quality.

3) Choose titanium rod suppliers with reliable quality assurance and advanced production technology: High-quality titanium rod suppliers usually have a sound quality management system and advanced production technology. Choosing such a supplier can ensure that the performance and quality of the purchased titanium rods are guaranteed.

In summary, the specifications of titanium rods are customized according to specific application scenarios and needs. Choosing the appropriate titanium rod specifications can not only improve the efficiency of the use of titanium rods, but also ensure the quality and performance of the products. Therefore, when purchasing titanium rods, we need to fully understand customer needs and application scenarios in order to choose suitable titanium rod specifications and suppliers.