Total Cracking Of Titanium Alloy Welding?4 Core Skills + Key Details, Completely Solve The Problem!

Total Cracking Of Titanium Alloy Welding?4 Core Skills + Key Details, Completely Solve The Problem!

In key fields such as aerospace, shipbuilding, and medical equipment, titanium alloy has become an indispensable core material with its “hard-core advantages” of high strength, low density, and corrosion resistance. But it also has a headache “weakness"-it is easy to crack during welding, which directly affects the safety and service life of the structure.

In fact, titanium alloy welding cracks are not insurmountable. The key lies in controlling the four core links of “protection, heat dissipation, material selection, and pre-welding preparation”. Today we will disassemble the practical skills for everyone to help you easily solve the titanium alloy welding problem!

1. Build A Strong "Protective Shield”: Isolate Harmful Gases In All Directions

Titanium alloys are extremely sensitive to oxygen, nitrogen, hydrogen and other gases at high temperatures, and once they come into contact, they will form brittle compounds, which directly cause the welds to crack. Doing a good job of gas protection is the first step to successful welding!

1) There is no shortage of two-stage protection: argon gas is ejected from the nozzle during welding to cover the arc area in all directions to prevent air from invading the bath; at the same time, the welding torch is equipped with a protective drag cover to continuously “escort” the welded welds to avoid oxidation during cooling.

2) The temperature is up to standard and then "disarm": you must wait until the weld is cooled below 200℃ before you can evacuate the argon protective atmosphere to minimize the residue of harmful gases.

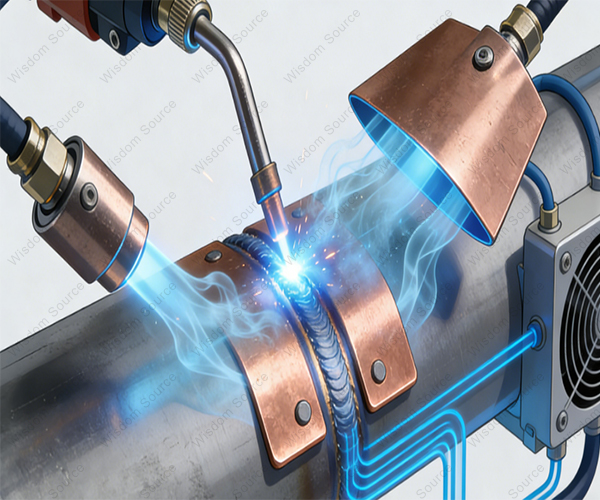

2. Rapid "Cooling Down”: Avoid Heat Accumulation And Cause Cracks

Titanium alloys have poor thermal conductivity, and heat can easily accumulate in welds and heat-affected areas during welding, resulting in coarse grains, decreased mechanical properties, and a significant increase in the risk of cracks.Efficient heat dissipation is the key!

1) Install a thermally conductive copper pressure plate: Install a copper pressure plate with high thermal conductivity on both sides of the weld, which can quickly conduct the heat generated by the welding and avoid excessive local temperature.

2) Water circulation to strengthen heat dissipation: cooling water is introduced into the copper pressure plate, and the heat dissipation efficiency is further improved through water circulation, and the temperature of the welding area is accurately controlled to prevent coarse grains.

3. Accurate "Matching”: Choose The Right Welding Method And Material

Suitable welding materials and methods can reduce the probability of cracks from the root cause, while ensuring that the performance of the welded joint is consistent with the base material.

1) Welding materials: composition matching + performance balance

• The selection of welding wire is the basis: welding wire with the same composition as the base material must be selected to ensure that the chemical composition of the welding joint is uniform and the performance is close to that of the base material.

• Balance strength and toughness: adjust the performance matching according to the use scenario. For working conditions with high toughness requirements, the strength of the welded joint can be appropriately reduced and the tendency to crack can be reduced.

2) Welding method: select as needed + strictly control parameters

Welding Method |

Core Advantage |

Applicable Scenarios |

Key Precautions |

Tungsten argon arc welding (TIG welding) |

Stable arc and high weld quality |

Larger thickness titanium alloy sheet |

Precise control of arc heat input to ensure weld forming |

Plasma arc welding |

Concentrated energy and fast welding speed |

Welding that requires efficiency |

Argon-hydrogen mixture for protective gas, strictly control the hydrogen content (avoid the formation of hydrides and cause brittle cracking) |

4. Good Preparation: Pre-Welding Preparations Cannot Be Omitted

The degree of fineness of preparation before welding directly affects the quality of welding.These two details must be in place!

• Thoroughly clean the welding area: Use mechanical polishing or chemical cleaning to remove oxide film, grease, moisture and dust from the welding area. The oxide film will hinder fusion, grease and moisture will produce pores, and dust will introduce impurities. These are the “hidden dangers” of cracks.

• Precise adjustment of equipment air pressure: too low air pressure will cause insufficient flow of protective gas and cannot isolate the air; too high air pressure will produce turbulence and affect the protection effect. According to the requirements of the welding process, the air pressure needs to be adjusted to a stable state to ensure that the gas evenly covers the welding area.

There is no “shortcut" to titanium alloy welding, but as long as the protection is in place, the heat dissipation is controlled accurately, the material selection is correct, and the preparation before welding is sufficient, cracks can be effectively avoided and the welding quality can be guaranteed. Whether it is a high-precision component of aerospace or a key component of medical equipment, following these techniques can give full play to the “advantages” of titanium alloy and escort the safe and stable operation of various types of equipment!