Analysis On The Processing Technology And Application Prospects of TC6 Titanium Alloy

Analysis On The Processing Technology And Application Prospects of TC6 Titanium Alloy

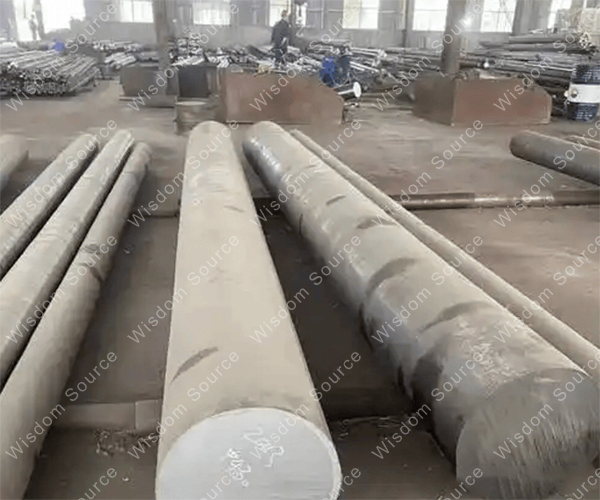

Titanium alloy, especially TC6 titanium alloy, as a high-performance two-phase titanium alloy, with its low density, high strength and excellent corrosion resistance, it has shown a wide range of application potential and value in many industrial fields. This article will take TC6 titanium alloy as an example to discuss the processing technology of titanium alloy in depth.

In the aerospace field, the application of TC6 titanium alloy is particularly critical. Its excellent mechanical properties and corrosion resistance make it the material of choice for key parts such as aircraft engine blades, landing gear, and airframe structure. In order to meet the high requirements of aerospace and spacecraft materials, the processing technology of titanium alloy has been continuously optimized and innovated, such as the use of precision casting, forging and heat treatment technologies to ensure that the performance of the material is fully utilized.

In the chemical and petrochemical industries, TC6 titanium alloy is also widely used. Equipment and pipelines in these industries often need to face harsh environments such as high temperature, high pressure, and strong corrosion. The processing technology of titanium alloy is mainly reflected here in the balance of corrosion resistance and high strength. Through the use of advanced welding and surface treatment technology, titanium alloy equipment can operate stably for a long time in these harsh environments.

The demand for titanium alloys in the shipbuilding industry is also growing day by day. With the trend of large-scale and ocean-going ships becoming more and more obvious, the requirements for hull materials are also getting higher and higher. TC6 titanium alloy, with its low density and high strength, provides more possibilities for the design of the hull structure.In terms of processing technology, the welding and cutting technology of titanium alloy has been widely used to meet the high material requirements of the hull structure.

The automotive industry also benefits from the processing technology of titanium alloys. With the continuous development of automotive lightweight technology, titanium alloy has become a leader in automotive lightweight materials due to its low density and high strength characteristics. In terms of processing technology, the stamping, stretching and heat treatment technologies of titanium alloys have been continuously optimized and innovated to ensure the performance and quality of automotive parts.

However, the processing technology of titanium alloy is not without challenges. High raw material costs and complex processing processes limit its promotion in some cost-sensitive applications. Therefore, the development of new processing technologies and the optimization of process parameters to improve production efficiency and reduce costs have become an important research direction of titanium alloy processing technology.

In order to promote the further development of titanium alloy processing technology, it is necessary to strengthen industry-university-research cooperation and cross-disciplinary exchanges. By integrating the resources and technical advantages of all parties, we will jointly overcome the technical problems of titanium alloy processing and application. At the same time, it is also essential to strengthen the research and testing of the properties of titanium alloys to better understand their performance characteristics and scope of application.

Looking to the future, with the continuous progress of science and technology and the continuous development of industry, titanium alloy processing technology will become more mature and perfect. In traditional fields such as aerospace, chemical industry, petrochemical industry, shipbuilding and automobiles, titanium alloy will continue to give full play to its unique advantages and promote the progress and upgrading of related technologies. At the same time, in emerging fields such as new energy and intelligent manufacturing, titanium alloys will also show their huge application potential and value. I believe that in the near future, titanium alloy will become one of the important forces to promote industrial development and make greater contributions to the sustainable development of human society.