Diversity and Application Selection Of Titanium Plate Surface State

Diversity and Application Selection Of Titanium Plate Surface State

Titanium plate, as a high-performance metal material, is widely used in aerospace, medical, chemical, electronics and many other fields. The choice of its surface state is essential to meet the needs of different applications. Titanium plates can have a variety of different surface states, which depend on the requirements of production and processing and the needs of specific applications. The following is a detailed analysis of the common surface states of titanium plates:

1. Hot Rolled Surface:

Hot rolling is a basic method of titanium plate manufacturing. During the hot rolling process, the titanium plate is strongly pressed by the rolling mill at high temperature to form a plate with a rough surface. This surface state usually has indentation and oxide skin during rolling, and requires subsequent processing and surface treatment, such as pickling or polishing, to meet the needs of specific applications. Titanium plates with hot-rolled surface conditions are commonly used in structural parts and components with low surface requirements.

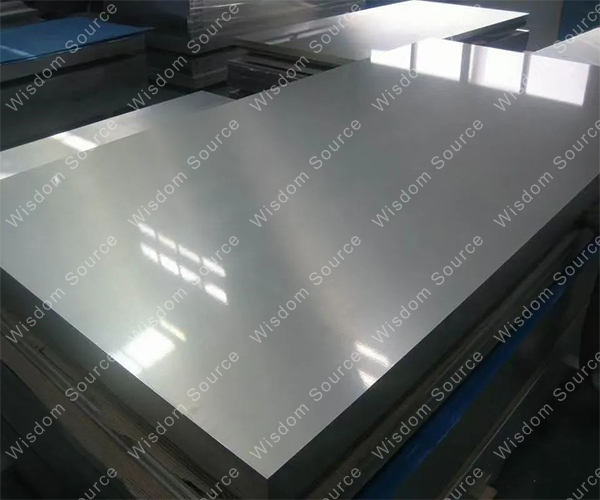

2. Cold Rolled Surface:

Unlike hot rolling, cold rolling is the rolling of titanium plates at room temperature. This method can obtain a smoother and more uniform surface quality. Titanium plates in the cold-rolled surface state have lower roughness and higher gloss, and are suitable for some applications with high surface quality requirements, such as medical equipment, food processing equipment, and precision electronic components.

3. Pickling Surface:

Pickling is a surface treatment method that removes oxides, dirt and undesirable surface layers from the surface of titanium plates through the chemical action of an acid solution. The surface of the titanium plate after pickling is cleaner and brighter, and its corrosion resistance is improved. Titanium plates in this surface state are commonly used in fields such as chemical equipment and marine engineering.

4. Polished Surface:

Polishing is the treatment of the surface of the titanium plate by mechanical or chemical methods to achieve a highly smooth and reflective appearance. Titanium plates in polished surface state have excellent visual effects and feel, and are commonly used in applications that require exquisite appearance, such as jewelry, high-end architectural decoration, and works of art.

5. Sandblasted Surface:

Sandblasting is a method of cleaning and changing the surface of titanium plates by spraying sand particles under high pressure. The surface of the titanium plate after sandblasting exhibits uniform roughness, which increases the friction and wear resistance of the surface. Titanium plates in this surface state are commonly used in non-slip floors, mechanical parts, and applications that require increased surface roughness.

6. Anodized Surface:

Anodizing is an electrolytic treatment method that improves the corrosion resistance and hardness of titanium plates by forming a dense oxide layer on the surface. The surface of the anodized titanium plate has better wear resistance, weather resistance and chemical resistance. Titanium plates in this surface state are commonly used in specific applications such as electronic components, chemical pipelines, and marine facilities.

7. Selection Suggestion:

Each titanium plate surface state has unique characteristics and application areas. When choosing, specific requirements such as appearance requirements, corrosion resistance, friction properties and assembly requirements should be considered. In order to ensure the selection of the appropriate surface state, it is recommended to have a detailed discussion with the material supplier or manufacturer to understand the characteristics and scope of application of different surface states in order to make an informed decision.

In summary, the diversity of surface states of titanium plates provides a wide range of options for different applications. Through the reasonable selection and use of titanium plates with different surface states, the needs of various complex applications can be met and the performance and reliability of the product can be ensured.