Full Analysis Of Titanium Tube Annealing Process: Principle, Process and Precautions

Full Analysis Of Titanium Tube Annealing Process: Principle, Process and Precautions

1. Introduction

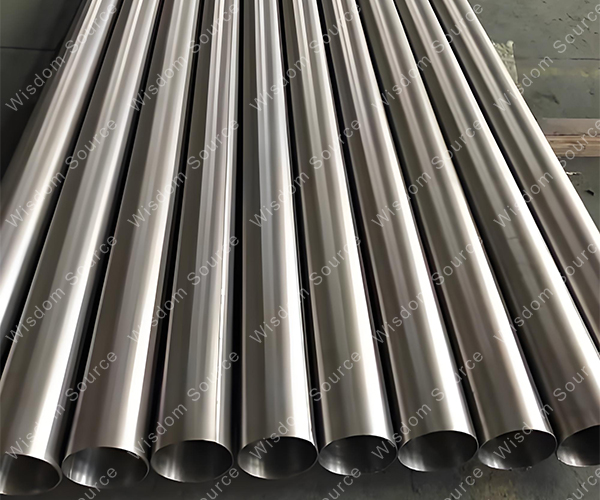

Titanium tube annealing is an important heat treatment process. It changes the organizational structure and performance of titanium tube by controlling the heating and cooling process, thereby improving key parameters such as corrosion resistance and strength. This article will analyze in detail the basic principles, processes and precautions of the titanium tube annealing process.

2. Basic Principles Of Titanium Tube Annealing Process

The basic principle of titanium tube annealing is to heat the titanium tube to a certain temperature and control the cooling speed within a certain period of time, thereby eliminating the stress generated during processing, improving grain refinement, and improving the performance of the titanium tube.

3. The Process Of Titanium Tube Annealing Process

1) Pre-treatment: Clean the titanium tube to remove impurities such as oil stains and oxide layers to ensure the cleanliness of the surface of the titanium tube.

2) Heating treatment: Put the pre-treated titanium tube into an annealing furnace, and set the heating temperature and time according to the specific materials and requirements. It is heated in a protective atmosphere to prevent oxidation of the titanium tube.

3) Cooling treatment: After the heating is completed, the titanium tube needs to be cooled at different temperatures to control the lattice structure and performance of the titanium tube.

4) Post-treatment: After the annealing is completed, the titanium tube is cleaned and inspected to ensure that the quality of the titanium tube meets the requirements.

4, Precautions For The Annealing Process Of Titanium Tube

1) Oxidation problem: Titanium tubes are easily oxidized during annealing, so they need to be heated and cooled in a protective atmosphere.

2) Process adjustment: Different types of titanium tubes need to adopt different annealing processes, and reasonable adjustments need to be made according to the actual situation.

3) Temperature and speed control: During the heating and cooling process, the temperature and speed need to be strictly controlled to avoid problems such as grain growth and hardness reduction.

4) Operating procedures and safety requirements: When performing the titanium tube annealing process, the corresponding operating procedures and safety operating requirements must be strictly observed to ensure the safety and stability of the operation process.

5. Conclusion

Through the introduction of this article, I believe readers have a more comprehensive and in-depth understanding of the titanium tube annealing process. In actual operation, reasonable adjustments and controls need to be made according to specific circumstances and process requirements to ensure the performance and quality of titanium tubes.