Analysis Of Thermal Expansion Properties And Yield Of TA18(Ti Gr9) Titanium Alloy

Analysis Of Thermal Expansion Properties And Yield Of TA18(Ti Gr9) Titanium Alloy

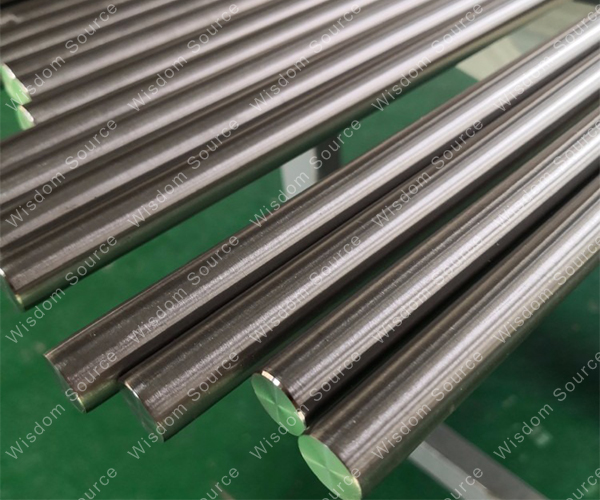

TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy, an alloy mainly composed of titanium (Ti), aluminum (Al) and a small number of other elements, has a wide range of applications in aerospace, chemical industry, metallurgy and other fields. Its unique thermal expansion properties and yield characteristics show important application value in high temperature environments.

1. Thermal Expansion Performance Analysis

Thermal expansion performance refers to the ability of a material to change its volume or linear size when its temperature changes. The coefficient of thermal expansion of TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy is relatively low, which means that it is not easy to undergo significant dimensional changes when working for a long time under high temperature conditions.

Specifically, the linear expansion coefficient of TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy is (8.0±0.5)×10⁻⁶/℃, which exhibits good stability over a wide temperature range. This low thermal expansion characteristic makes TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy an ideal choice for high-temperature working environments such as heat exchangers and engine components, which helps to reduce structural deformation and stress concentration caused by thermal expansion and contraction.

2. Yield Analysis

Yield is an important indicator to evaluate the ability of a material to resist permanent deformation. TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy has high yield strength, especially in high temperature environments, it can still maintain good mechanical properties. Experimental data show that the yield strength of the alloy at room temperature is 650 MPa, while at 450℃, its yield strength can still be maintained at more than 500MPa. This characteristic makes TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy have strong deformation resistance when subjected to large loads or high-speed movement, so as to meet the high load requirements in aerospace and other harsh environments.

3. Conclusion

In summary, TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy, with its excellent thermal expansion properties and yield, has demonstrated excellent stability and reliability in high temperature and high load environments. Its low coefficient of thermal expansion and high yield strength ensure the performance of the material under complex working conditions, so it is widely used in aviation, aerospace and chemical equipment and other fields. An in-depth understanding of these performance characteristics of TA18(Ti Gr9, Ti-3Al-2.5V) titanium alloy is of great guiding significance for improving the design and application level of products in related fields.