Titanium Alloy: A lightweight Alloy Material With Excellent Performance

Titanium Alloy: A lightweight Alloy Material With Excellent Performance

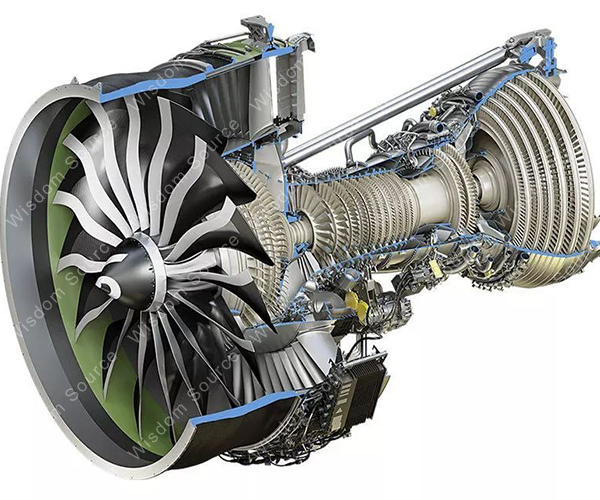

Titanium alloy, as an alloy based on titanium and composed of other alloying elements, is widely used in many fields because of its unique properties.

The classification of titanium alloys is diverse, including structural titanium alloys, heat-resistant titanium alloys, and α-type, β-type, and α+β-type titanium alloys divided by crystal structure.

1. The Development History Of Titanium Alloy

Since the 1950s, titanium alloy has emerged and gradually developed into an important structural metal. The United States successfully developed the first practical titanium alloy-Ti-6Al-4V alloy in 1954. Its excellent properties make it an ace product in the titanium alloy industry. With the advancement of technology, the heat resistance, corrosion resistance, strength and other properties of titanium alloys have been continuously improved and optimized.

2. The Main Categories Of Titanium Alloys

The classification of titanium alloys is mainly based on the difference in phase transition temperature and phase separation content. At room temperature, titanium alloys can be divided into three categories: α alloys, (α+β) alloys and β alloys.Among them, α-titanium alloy has stable structure, good wear resistance and oxidation resistance; β-titanium alloy has the characteristics of high strength and poor thermal stability; (α+β) Titanium alloy has excellent overall performance and is suitable for various heat treatment processes.

3. Performance Characteristics Of Titanium Alloy

1. Low Density And High Specific Strength: The density of titanium alloys is generally only 60% that of steel, but its strength is close to or even exceeds that of many alloy steels. This makes titanium alloy an ideal material for manufacturing lightweight and high-strength parts.

2. High Thermal Strength: The operating temperature of titanium alloy is much higher than that of aluminum alloy, which can maintain the required strength at medium temperatures, especially suitable for working in high temperature environments.

3. Good Corrosion Resistance: Titanium alloy exhibits excellent corrosion resistance in humid atmosphere and seawater media, and has good resistance to a variety of corrosive media.

4. Good Low Temperature Performance: Titanium alloys can still maintain their mechanical properties at low temperatures, and titanium alloys with very low gap elements can still maintain a certain plasticity at very low temperatures.

These performance characteristics of titanium alloy have made it widely used in aerospace, chemical industry, medical and other fields. With the continuous progress of technology, the performance of titanium alloys will be further optimized and improved, and their application fields will be more extensive.